| Custom specifications are available. | |

| Operating system | Liming operating system in both Chinese and English |

| Frame design | Type 1 wall plate frame design |

| Type 2 new standing frame design | |

| Main motor power | 11kW with reducer |

| Drive mode | Chain and gear |

| Line speed of roll forming machine | 15m/min (higher speed is available as per customer’s requirements) |

| Hydraulic group power | 4kW |

| Electric standard | 380V/50HZ/3PH or as per customer requirements |

| PLC | Siemens |

| Touch screen | Siemens |

| Inverter | Schneider |

| Encoder | Omron |

| Accessory options | 1. Uncoiler / decoiler |

| 2. Hydraulic pre-shearing device | |

| 3. Stacker | |

| 4. CE certificate | |

|

Contact our sales team for more information. |

|

Other Products

|

|

|

|

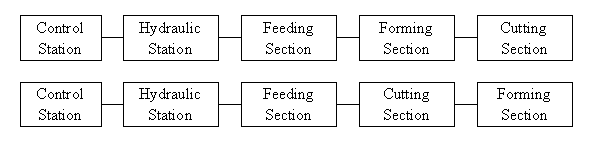

C Purlin Pre Punch and Cutting |

C Purlin Pre Punch Post Cutting |

C and Z Purlin Forming Machine |

|

|

|

|

Boltless Profile Forming Machine |

Corrugated Profile Forming Machine |

Garage Door Forming Machine |

|

|

|

|

Ridge Cap Forming Machine |

Steel Housing Forming Mills |

Forming Mills Integrated in Container |

|

|

|

| Safety Guardrail Roll Forming Line | Z Purlin Pre-Punching and Post Cutting | Uncoiling / De-coiling Machine |

|

|

|

| Taper Profile with Inner Standing Seam | Taper Profile with Outside Standing Seam | Shelving Panel Forming Mill |

|

|

|

| Forming Machine 820 | Floor Deck Forming Machine | High Rib Forming Machine |

|

|

|

| Quick-Change Profile Roll Forming Machine | Widespan Profile Forming Machine | OPP Film Forming Machine |

|

|

|

| Adjustable Hemming Machine | Pneumatic Seamer | C Purlin Stacker |

|

|

|

| Slitting, Cutting and Recoiling | Forming Mills Integrated in Container | Pipe Folding Machine |

|

|

|

| Blending and Curving | Electric Seamer | Simple Electric Seamer |

|

|

|

| L1000826 Profile | L1010163 Profile | L1020826 Profile |

|

|

|

| L1000495 Profile | 470 Profile | 1305-43 Profile |

|

|

|

| Profile |

Double Layer Roll Forming Machine |

Heat-Preserving Cassette Profile Forming Machine |

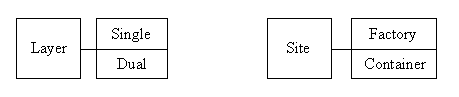

Klassifikation:

Klassifikation:Vores tag / væg panel valsning maskiner kan klassificeres som følgende måde i følgende kategorier:

Betaling:

30% TT før produktionen, 70% TT før forsendelse.

Emballage og forsendelse:

Læg beholderen, fix i de punkter, og derefter sende ad søvejen.

30% TT før produktionen, 70% TT før forsendelse.

Emballage og forsendelse:

Læg beholderen, fix i de punkter, og derefter sende ad søvejen.

1. Drift:Stand station med styresystem til normal drift, og lille controller med lange kabel til reparation og justering.

2. Fremstilling: De fleste medarbejdere med mere end 10 års erfaring.

3. Kontrol hardware: Siemens, Panasonic, etc.

4. Elektriske komponenter:Schneider.

5. Hydrauliske komponenter:Nogle fra Kina førende fabrikker, og nogle fra Tyskland.

6. Tjeneste:Dygtige ingeniører kan flyve til noget land efter behov.

Service:

Liming Garantier sin væg / tag panel valsning maskiner til en periode på et år fra datoen for maskinens forlader vores fabrik, hvis betjenes korrekt og vedligeholdes og anvendes under normale forhold.

Installation:

Hvis der er behov installation, vil Liming sende tekniker til køber fabrik i udlandet for at hjælpe med installation og idriftsættelse af maskinen gratis, men køber vil være ansvarlig for at bistå i Liming tekniker for at få visum, og betale for air roundtrip billet, indkvartering og lokal transport.

2. Fremstilling: De fleste medarbejdere med mere end 10 års erfaring.

3. Kontrol hardware: Siemens, Panasonic, etc.

4. Elektriske komponenter:Schneider.

5. Hydrauliske komponenter:Nogle fra Kina førende fabrikker, og nogle fra Tyskland.

6. Tjeneste:Dygtige ingeniører kan flyve til noget land efter behov.

Service:

Liming Garantier sin væg / tag panel valsning maskiner til en periode på et år fra datoen for maskinens forlader vores fabrik, hvis betjenes korrekt og vedligeholdes og anvendes under normale forhold.

Installation:

Hvis der er behov installation, vil Liming sende tekniker til køber fabrik i udlandet for at hjælpe med installation og idriftsættelse af maskinen gratis, men køber vil være ansvarlig for at bistå i Liming tekniker for at få visum, og betale for air roundtrip billet, indkvartering og lokal transport.

Tag: C Z purlin Forming Machine | Pipe Folding Machine | Bølgepap profil Forming Machine | Bundløse profil Forming Machine

English

English Russian

Russian Spanish

Spanish French

French Arabic

Arabic Portuguese

Portuguese